Design

Build

Carefully engineering each aspect of a project maximizes savings and provides a turn-key solution with no surprises.

There are many factors to consider when engineering a custom lighting solution. Capacity’s engineers will design a solution to reduce energy expense, reduce maintenance cost, and improve the light output. Properly placed lighting fixtures will evenly illuminate work areas to optimize productivity and increase safety.

Data loggers are used to collect data to analyze occupancy, usage and functionality. A Daylight Harvesting Study uses data loggers to record daylight and digital image processing for daylight analysis. By collecting concrete data, Capacity can give an accurate payback analysis as well as design an optimal custom lighting solution for you.

Energy projects should not be considered capital improvements, instead they should be looked at as investments. We generate a financial report showing the value of the investment, using your internal discount rate.

While energy reduction is motivating factor in many projects, maintenance savings or tax savings can also justify a project. Projects are designed to qualify for federal, state and local incentive programs. Many utility companies provide significant rebates to install energy efficient lighting that often pay a good percent of the installed project cost. A group re-lamp or replacing many of the lights at one time, eliminates almost all required maintenance for the first three years. Capacity completes a maintenance study that projects the reduction in labor to repair lights, and the reduction of inventory of replacement parts.

Sustainability and green initiatives are increasingly beneficial for positive public relations. Even someone who is not environmentally concious will agree the savings are substantial.

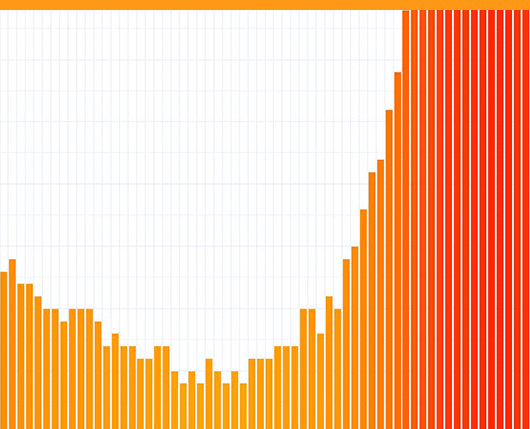

The example above uses real numbers from a lighting project that saved about $15,000 a year on energy cost, and after implementation, the project avoided burning 125,097 pounds of coal annually.

Capacity offers a turn-key solution. We handle everything from initial design to completing rebates. Our account representative and on-site project manager will ensure that your project will run smoothly, with no interruption to your business, from start to finish.

Capacity provides a single point of contact for the entire project scope. Your account representative simplifies the project for you while efficiently managing engineering, design and installation.

Capacity schedules around your operations. We are familiar with heavy industrial, warehousing and manufacturing. From the Engineered Lighting Study to installation, your business process will continue to run without interruption.